中文

ENGLISH

中文

ENGLISH

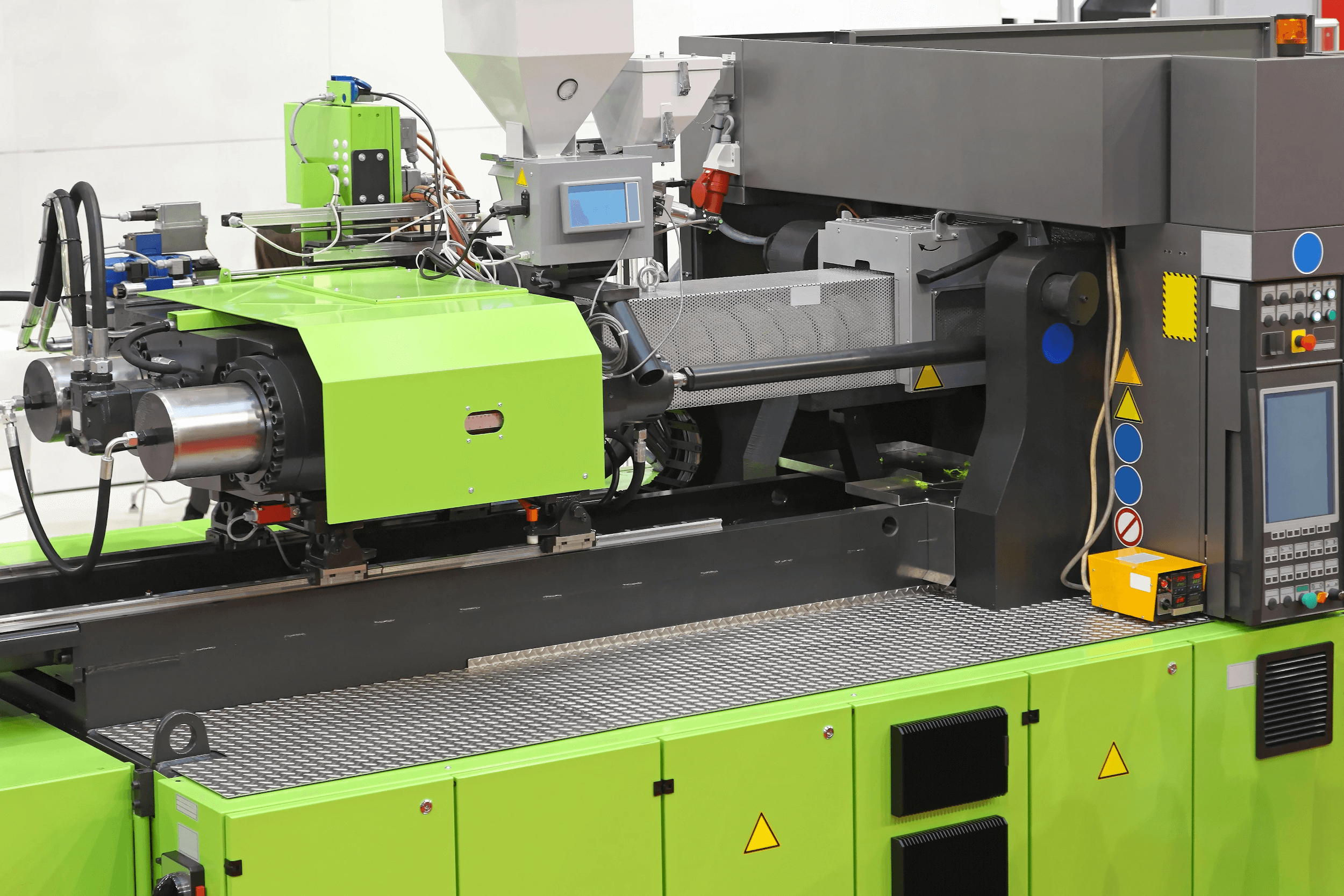

ABS plastic vowin.cn/en/News/news1251.html' target='_blank'>vowin.cn/' target='_blank'>molding manufacturers are among the most sort after injection molding manufacturers. The reason being, ABS (Acrylonitrile Butadiene Styrene is the perfect plastic for molding. Consumers around the globe wide prefer ABS for injection molding.

The material has an impervious and shiny surface because of the styrene content. The polybutadiene is responsible for the toughness of the product. It even ensures product robustness at low temperatures. In addition, manufacturers are able to modify certain characteristics of ABS plastic to meet the needs of the product.

ABS chemical structure not only offers robustness but also ensures flexibility and versatility.

The Acrylonitrile Butadiene Styrene, the opaque amorphous polymer and thermoplastic are used for producing high-quality plastic parts. You will notice that we using Thermoplastic instead of thermoset. The reason has something with the material’s reaction to heat.

It is possible to heat thermoplastic to a melting point. They have a glass transition. In order to turn, them to liquid you would have to heat them up to 221 degrees Fahrenheit. This temperature is specifically for ABS. For other thermoplastics, you would have to check with their temperature specification.

The great thing about ABS plastic is that you can heat it to a melting point, cool it down and then heat it again. There will be little to no degradation in this process. The first time you heat a thermoset a chemical change takes place that is irreversible. So, when you try eating it the second time, it would burn.

The recyclability factor of a thermoset makes it less appealing to the eco-friendly injection molding companies. The companies would prefer having materials that can be easily recycled. Therefore, manufacturers turn towards materials like ABS.

In addition to being recyclable, ABS is an amorphous material. It means the material lacks crystalline solids ordered characteristics. Thus, Making it a better choice in comparison to several other plastic materials.

Usually, the manufacturer uses the emulsion process to polymerize ABS. In lame man terms, it means the combination of several products that usually do not blend in into a single product. Milk is a common example of an emulsified product.

Another effective technique to create ABS is a patented process, Continuous Mass Polymerization. However, manufacturers rarely use this method. In general, people around the world prefer using the emulsion process of ABS development.

Since ABS is a thermoplastic material, thus you can easily recycle it. So, it is safe to say you would be making ABS from ABS.

We often come across a question: Why do consumers prefer ABS? There are several reasons for it. For starters, it melts at a relatively low temperature and machine friendly. It is extremely easy for the injection molding machines to handle the material.

You can easily execute 3D printing on the FDM machines or other injection moulding techniques using ABS. Another reason for people to choose ABS is that it is cost-effective. You have to pay $1.50 or so for a pound. However, it is not wise to use ABS plastic in situations that require high temperatures. Its low melting point will surely lead to undesired results.

The creative and sophisticated now prefer the fused deposition molding 3D printing technique of other more commonly used techniques. Some of these techniques include SLM, SLS, SLA or much more. One of the reasons for using fused deposition modeling is you tend to get access to ABS parts easily.

ABS plastic molding manufacturers need to ensure that there are no hold-ups in terms of material especially during the transition from prototype to production. After all, ABS is the perfect material for several applications.

You can easily shape ABS, glue it, sand it or paint it. These characteristics allow it to blend in well with a number of products. Unlike some plastics, it is possible to change ABS colors, get good finishes and enjoy robustness.

Due to these reasons, manufacturers often use it for enclosures that may have glossy surfaces and different textures. ABS has the ability to add to the aesthetic sense of the product.

You might have heard rumors that ABS is a toxic material. However, you are might surprise to know that ABS is way less harmful in comparison to many other plastics that we use. ABS does not have any known carcinogens.

In addition, we have never heard about any side effects once exposed to ABS plastic. Nonetheless, we would not recommend ABS for medical implants. Therefore, for medical implants try using some other material.

The amazing material is extremely sturdy especially in terms of structure. Due to this property, the material is widely used. You can see it in cameras, protective housings, packaging among others. ABS is the perfect choice when you are looking for strong, inexpensive and stiff material.

Below, we have come up with the basic properties of ABS.

| Property | Value |

| Technical Name | Acrylonitrile butadiene styrene |

| Shrink Rate | 0.5-0.7 % |

| Specific Gravity | 1.06 |

| Flexural Strength | 10800 PSI (74 MPa) |

| Tensile Strength | 6600 PSI (46 MPa) |

| UL RTI | 140°F (60 °C) |

| Heat Deflection Temperature | 208 °F at 66 PSI (98 °C at 0.46 MPa) |

| Typical Injection moulding Temperature | 400 – 460 °F (204 – 238 °C) |

| Glass Transition | 221 °F (105 °C) |

| Chemical Formula | (C8H8)x· (C4H6)y·(C3H3N)z) |

ABS is an excellent material for injection molding processes. It is among the most common plastics that are used in 3D printing and OEM part production. Its ability to melt at low points makes it excellent for prototyping. The low glass transition temperature further adds to its appeal.

Since you can easily melt it to any shape you want, you can use it anywhere and everywhere. The additional benefits of reshaping it make it the best material for injection molding. Despite the number of times you reshape it, there is very limited chemical degradation. Below are some of the major benefits that it offers:

ABS is widely used in a number of applications. You might be surprised to know that the laptop or computer that you are currently using has a keyboard made of ABS. The LEGO bricks are also made up of ABS plastic.

The manufacturer uses ABS plastic for making wall socket’s face guards. They also use it for other protection housing power tools. ABS is also a common material in the automotive field. It is used for car interior as well as for the plastic alloys.

It is also common in the construction industry. The tubes and the corrugated plastic structure use ABS. You can shape it as per your desire and enjoy bright, vibrant colors.

ABS also comes handy in protection headgear including helmets and other hard hats. In addition, you will find ABS in kitchen utensils, vacuum cleaners, printers, musical instruments, and faxes. It is also widely used in the toy industry.

In addition, ABS is an excellent choice for plastic items that you plan to place outdoor. It is robust and can withstand harsh weather conditions. It stands well against winds, storms, and rains. However, to improve its lifespan, try to protect it from UV rays. Also, avoid using it in extreme weather conditions without proper protection.

ABS plastic molding manufacturers are able to handle a broad range of industries. Its robustness, reusability, and flexibility make it the top choice for several applications. The automobile industry, toy industry, house protection, and several other industries heavily depend on ABS.

ABS is a machine-friendly material. In order to take its full advantage, you need to reach out to experienced ABS plastic moulding manufacturers. They will be able to shape and design the plastic as per your needs.

There are no better manufacturers then Kaito Mould. They have years of experience and the latest technology to deliver high-quality products. Reach out to them today, and get answers to all your queries.