中文

ENGLISH

中文

ENGLISH

plastic injection manufacturer is quite famous in plastic products industry. Every industry uses multiple plastic products. Similarly, the scope of human activity is also associated with it. The use of plastic from building materials and household appliances to kitchen utensils.

The most popular method for manufacturing various products is plastic injection manufacturer technology. Moreover, modern equipment provides an opportunity to automate the production process.

And receive products with excellent technical characteristics in a short time with minimal investment. Polymer products are recyclable. Therefore, they are environmentally friendly material.

Injection molding is a manufacturing process in which liquid plastic is injected under pressure into a metal mold. Evenly distributed over it and solidifies. Subsequently, this is the most common method of large-scale manufacturing of plastic products.

The injection molding process requires sophisticated equipment and serious technical training. However, under the supervision of experienced professionals, the costs justify themselves. And the result is a product of excellent quality.

Large-scale and mass production of plastic parts involves a complex process. For injecting molten plastic under high pressure into a prepared injection mold made of metal. Furthermore, the liquid mass evenly fills the volume and crystallizes, acquiring the desired shape.

Thanks to plastic injection manufacturer molding technology. Moreover, it is possible to obtain high-quality products. To implement the method, sophisticated expensive equipment is used that provides high performance.

Using this method, almost half of the polymer parts are produced. Granules of thermoplastics, as well as thermosetting powders. Which give finished products the required physical and operational qualities. Simultaneously, these are used as raw materials for the production process.

Using this method, you can produce almost any plastic product. There are no restrictions on the size or number of parts. Here is a partial list of what can be produced plastic injection manufacturer technology:

Many plastic injection manufacturer choose a cheaper method of production – casting in silicone mold. However, often this choice brings even greater cash costs. And does not guarantee excellent quality.

High accuracy of the finished product. The supply of liquid plastic under pressure allows it to evenly distribute in shape, filling even the smallest holes.

The ability to receive parts of any complexity, including with very thin walls. For the manufacture of products, a metal mold is made. Similarly, the design of which takes into account all the small details of the future product.

As a result, plastic injection manufacturer can get both simple and very complex product, with many holes and bends.

The minimum need for machining the product. More often than not, the finished product does not require any processing. Moreover, exceptions are very complex products. However, in this case, the improvements are minimal.

Unlimited finished products.

The metal mold, which is created before production, will last a very long time. Subsequently, with its help you can make any number of products.

Low cost subject to the manufacture of a large batch.

The more products will be manufactured, the cheaper the cost of one copy. Because the main budget is spent at the stage of preparatory work. Hence, it is carried out only once.

At the same time, plastic injection manufacturer technology has its drawbacks.

The process of manufacturing plastic products by injection molding involves several stages. Generally, it can be divided into two groups:

Let’s consider these stages in more detail.

Preparatory work

Creation of 3D models of the future product. You can create a 3D-model according to the drawings, description or photograph. Three-dimensional modeling is carried out in a special program by an experienced specialist.

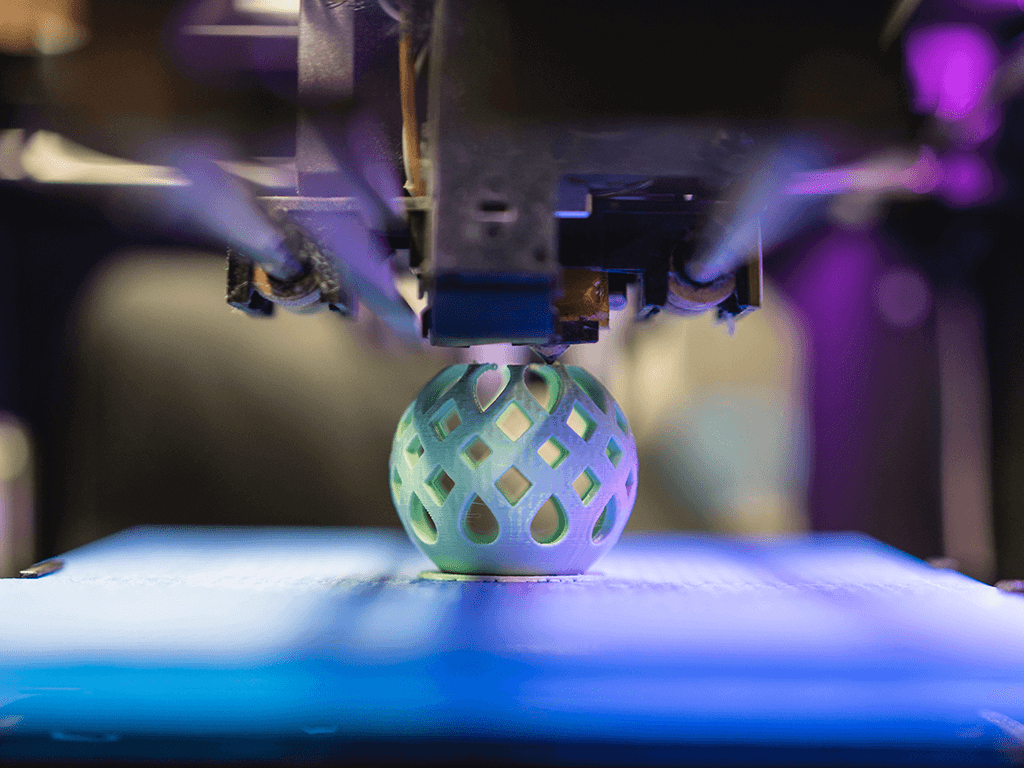

Prototype manufacturing.

After the 3D model is created and approved, you can create a prototype, i.e. sample of the future product. This is most often done using 3D printing.

A prototype is necessary in order to evaluate and test the future product.

If any inaccuracies were found, it is necessary to return to the first stage and finalize the 3D model.

Mold design.

This process is based on a 3D model of the future product. When designing, it is important for the plastic injection manufacturers to consider all the smallest details and subtleties.

Mold making.

The finished 3D model is divided into several parts. Moreover, each part is made separately. After which they are assembled into a mold.

Test casting.

Next, using the finished mold, the first copy is made. Furthermore, it is carefully studied and tested. If inaccuracies or flaws were found, the mold is being finalized.

Preparatory work lasts from several weeks to several months. However, this is an important stage in which plastic injection manufacturer should not rush. Because the quality of future products depends on it.

Submission of plastic to the mold under pressure. Moreover, the heated plastic is fed into the mold under high pressure.

Uniform distribution of plastic over the mold. Due to the pressure, the plastic is evenly distributed in shape filling even small holes.

Mold cooling and plastic hardening. Similarly, the cooling time depends on several parameters:

Delivery of the finished product.

After the mold has cooled, it opens to give the finished product.

As a rule, the plastic injection manufacturer by this method requires serious financial investments at the stage of preparatory work. However, the more pieces will be produced in the future, the lower the cost of one product. At the same time, quality remains high.

The production price is calculated individually, based on all of the product features. What the final cost may depend on

For the production of large batches of polymer products, plastic injection manufacturer technology of plastics is characterized by the advantages of high precision casting. By injecting the molten mass at an increased rate, uniform filling of the mold is ensured, including microscopic holes. Generally, the method is characterized by many advantages, due to which it is popular: