ProtoTools & Low-Volume Injection Molding

PROJECT – A 10 week time line to deliver 23 tools and 200 sets of parts to client for testing before full production tooling can be committed too.

ISSUE – After review only some minor changes are recommended to client. The primary issue was tooling department being near capacity which required flawless execution to hit deadline.

SOLUTION – 24 hour manufacturing to ensure we could satisfy this client and other tooling jobs in the pipeline.

RESULT – Week 8, tools complete, week 9 all parts delivered, 1 week early.

Learn more below…

Project Summary

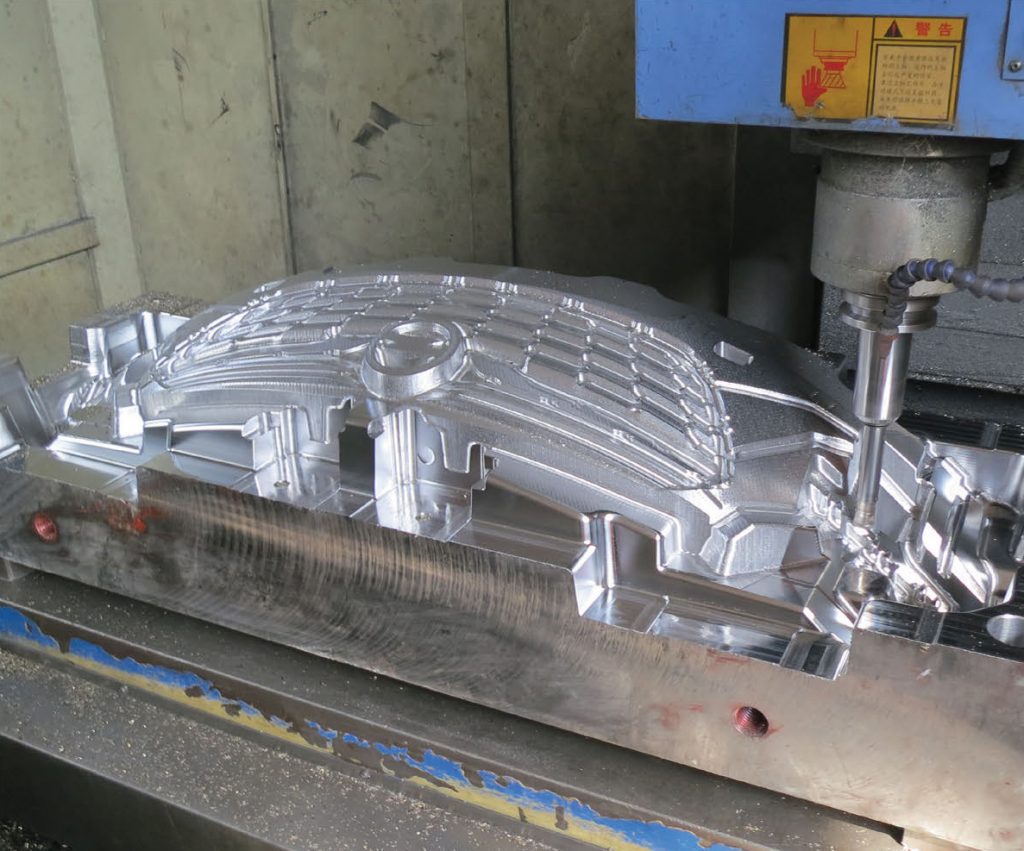

This project was a complete bumper package, front and rear. 23 tools needed to produce 200 sets of parts.

DFM – The DFM review period was 3 days between our report and the client review. Common design issues identified and adjusted for.

DAY 1 – Project starts, client confirms drawings and vowin.cn/' target='_blank'>mold fabrication begins.

WEEK 8 – Tooling complete, test parts run and shipped to client for review.

WEEK 9 – Client confirms test parts. HLH runs 200 sets and ships to the client the same week.

SERVICE:Â Rapid Tooling Package & Low-Volume Injection Molding.

QUANTITY:Â 23 Tools – 200 Sets Of Parts

MATERIALS TOOLING:Â Steel 45

MATERIALS PARTS: ABS

FINISHING: Painting & Chrome

LEAD TIME:Â 10 Weeks

This rapid tooling project was all about capacity, timing, and execution.

In rapid manufacturing we are always adjusting so we can serve all our clients needs. Rapid manufacturing requires rapid scheduling adjustments at times.