Injection vowin.cn/en/News/news1251.html' target='_blank'>vowin.cn/' target='_blank'>molding is a process used to create products from both plastics and metals. Medical devices are often created through injection molding, as the process allows for intricate designs and tight tolerances.

Injection molding offers many benefits for medical device manufacturers, including versatility, speed, accuracy, and affordability. Devices created through injection molding are also typically more reliable and durable than those created through other manufacturing methods.

If you’re looking to create high-quality medical devices, injection molding is the process for you. Continue reading this post to learn how injection molding medical devices can help you.

What Is Injection Molding And How Does It Work?

Injection molding is a manufacturing process for creating parts from plastic material. It is commonly used for creating plastic parts and components, but can also be used to create objects made from other materials such as metal or glass.

It works by melting the plastic and injecting it into a mold. The molded part is then cooled and ejected from the mold. Injection molding is a versatile process that can be used to create parts of various shapes and sizes.

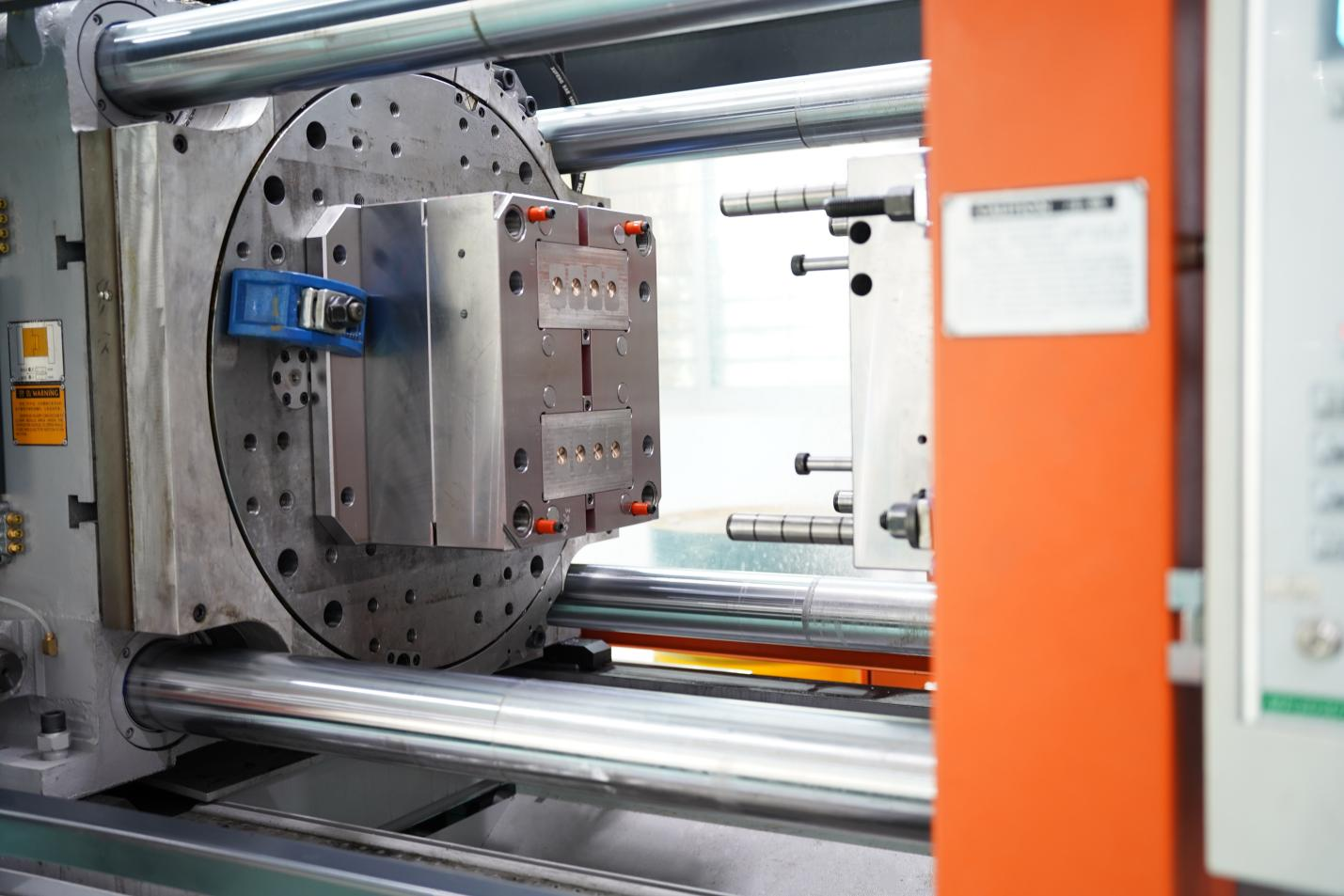

The injection molding machine consists of three main parts: the injection unit, the mold, and the clamping system. The injection unit melts the plastic material and injects it into the mold.

The mold is made up of two halves that are connected to the injection unit. The clamping system holds the two halves of the mold together during injection and cooling. Injection molding is a quick and efficient way to produce large quantities of identical parts.

Top 10 Benefits Of Injection Molding For Medical Devices!

Injection molding is a manufacturing process that involves injecting melted plastic into a mold to create various parts and products.

This process is often used for mass production, as it is fast and efficient. In addition, injection molding can be used to create highly intricate parts with tight tolerances.

Listed below are the top 10 benefits of injection molding for medical devices.

1. Reduced Lead Times and Costs.

Injection molding allows you to create large quantities of parts quickly, which can significantly reduce your production time and costs.

2. Higher Precision and Accuracy.

Injection molding produces parts with tight tolerances; it is a great option for creating medical devices that need to be highly precise and accurate in their function.

3. Greater Flexibility in Design.

The ability to precisely control the temperature and pressure of the plastic as it is being injected into a mold makes it easier to create complex designs without compromising functionality or quality.

4. Stronger Materials and Better Structural Integrity.

Many types of plastic used in injection molds are exceptionally strong, allowing medical devices made using this process to hold up well over time and resist cracking or breaking.

5. Improved Durability And Longevity.

As injection molded parts are made with stronger materials that have a greater resistance to wear and tear, they typically last longer than other types of medical devices.

6. Endless Customization Options.

Injection molding allows you to customize the color, texture, size, shape, and many other properties of your medical devices to meet the unique needs of your customers or patients.

7. Reduced Chances For Contamination Or Infection.

The tight tolerances created by injection molding make it difficult for bacteria or other contaminants to get trapped inside the device, minimizing the risk of infection or illness caused by your products.

8. Versatility across a Wide Range of Industries.

Injection molding can be used in a wide variety of industries, including medical, automotive, aerospace, electronics, and more.

9. Higher Safety Standards and Regulatory Compliance.

Due to the stringent safety requirements that apply to medical devices, many companies choose injection molding as their manufacturing process to ensure that they meet all necessary regulations.

10. Easy Scalability for Mass Production.

Because injection molding is such an efficient method for producing large quantities of parts quickly, it is ideal for companies with high production demands or who want to scale up their operations easily as their business grows.

Overall, injection molding is a highly effective manufacturing method that can be used to create a wide range of medical devices with precision and accuracy.

If you are looking for high-quality parts for your medical devices, then injection molding may be the right choice for you.

How Can Injection Molding Medical Devices Improve Patient Care?

Injection molding is a unique process that allows manufacturers to create precisely engineered medical devices that can help to improve patient care.

Whether it is manufacturing syringes or specialized tools for surgery, this process allows manufacturers to create highly precise and durable medical devices that can directly impact patient care.

Through injection molding, manufacturers can engineer durable materials and parts with intricate structures and shapes, helping to ensure that the devices are lightweight, flexible, and strong.

What’s more, injection molding often uses less material than other manufacturing processes, giving manufacturers greater control over the final product. Ultimately, it results in higher-quality medical devices that can better serve patients as they receive treatment for a wide range of conditions.

So if you’re looking for safer and more effective patient care, then look no further than injection molding medical devices.

5 Steps Involved In Producing A Medical Device Using Injection Molding!

1. Designing the Medical Device:

This is the first and most important step in the injection molding process. The design of the medical device must be created with precision to ensure that it functions properly and meets all safety standards.

2. Creating the Mold:

Once the design of the medical device has been finalized, a mold must be created. This mold will be used to shape the plastic during the injection molding process.

3. Injecting the Plastic:

The next step is to inject molten plastic into the mold. This plastic will take on the shape of the mold, creating the desired medical device.

4. Cooling and Ejection:

Once the plastic has been injected into the mold, it must be cooled. Once it has cooled, the mold is opened and the medical device is ejected.

5. Quality Control:

The final step in the injection molding process is quality control. This step ensures that the medical device meets all safety and quality standards.

What Are Some Of The Challenges Associated With Injection Molding Medical Devices?

Injecting medical devices poses many unique challenges. One of the main challenges is the need for accuracy and precision. When working with materials that are sensitive to temperature changes, it is crucial to maintain extremely tight control over the molding process to prevent defects or damage.

Another challenge is maintaining high-quality standards throughout production, as even small variations in part size or shape could require costly and time-consuming corrections at later stages of production.

Maintaining consistent temperatures throughout the injection molding process can be difficult since it requires precise control over temperature settings and environmental conditions.

In addition, contamination of the plastic material can have serious consequences for the final product, as it can lead to defective or unsterilized devices.

Molding medical devices often require specialized equipment and processes that can be costly and difficult to perfect, particularly when working with new or emerging materials such as plastics or biocompatible metals.

While these challenges may seem daunting at first glance, they are precisely what make working in the medical device industry so exciting and rewarding.

With careful planning and effective execution, it is possible to create high-quality molds that help ensure both patient safety and reliable product performance over many years of use.

How Will The Future Of Injection Molding Impact Patient Care?

In the future, the field of injection molding is likely to undergo significant changes that could impact the way that we care for patients. A key advancement is likely to be the development of more biodegradable and eco-friendly materials.

These materials could be used not only for medical devices and implants but also for drug delivery systems and even for organ replacements. For example, researchers are already working on developing a biodegradable heart valve that can generate new tissue around itself once it is implanted into the body.

Additionally, with growing concerns about the prevalence of antibiotic resistance, researchers will need to focus on developing “smart” devices that limit drug dosages based on patient needs in real-time.

At the same time, with advances in 3D printing technologies and materials, it is now possible to create high-quality, custom medical devices that can be easily adapted for use by each patient.

For example, a patient with limited mobility due to an injury or illness might benefit from an injection-molded leg brace designed specifically for their needs. In addition, new manufacturing techniques make it easier than ever before to produce complex shapes and intricate designs, allowing healthcare providers to develop drug injectors and other devices that can improve the efficacy and effectiveness of treatment regimens.

As such, advancements in injection molding will undoubtedly have a profound impact on patient care going forward.

How to Choose the Right Type of Machine And Supplier?

When deciding on a supplier for injection molding for medical devices, there are several factors you should take into consideration.

- First, it is important to carefully evaluate different suppliers based on their experience and track record in this particular industry. In general, companies that have been working with medical clients and manufacturing medical products will be your best bet, as they already have the expertise and knowledge necessary to produce high-quality products with efficiency and precision.

- In addition, you should also consider the type of machine that each supplier offers. Larger machines tend to be more powerful and capable of producing more complex parts at higher speeds. However, smaller machines can provide greater flexibility by enabling you to test different product ideas and designs before committing to larger prototyping runs from other suppliers.

- It is also important to consider the track record and reputation of potential suppliers. This can include things such as industry certifications, customer feedback, and manufacturing experience.

- In the end, choosing the right type of machine and supplier will depend on a range of factors specific to your needs and preferences.

By considering these factors carefully and focusing on quality over cost alone, you can ensure that you find the right machine and supplier for your injection molding needs.