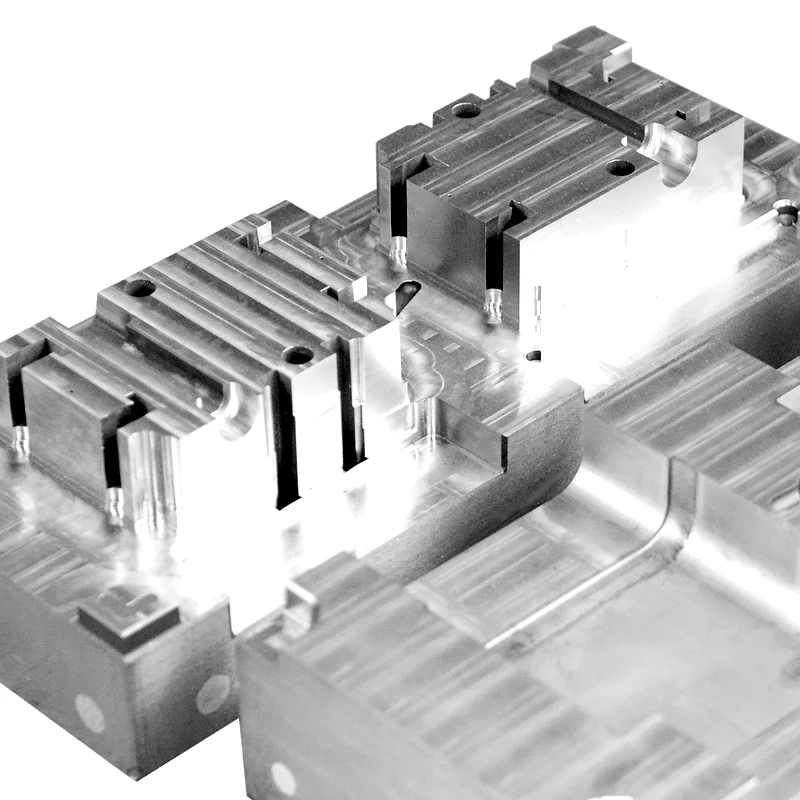

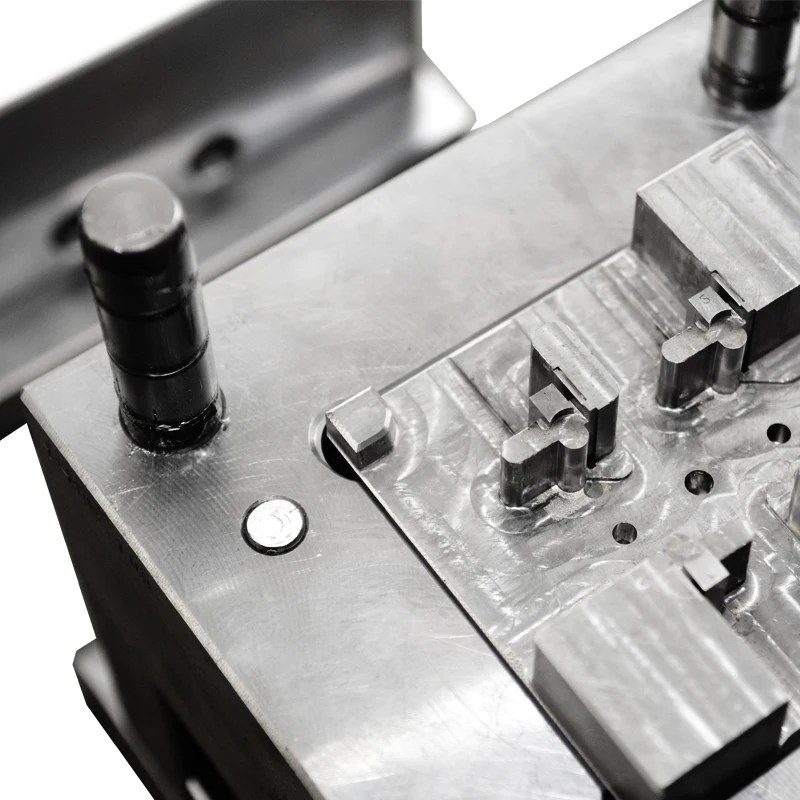

Custom Made Plastic 3D CAD Designed Plastic Injection Moulds Candle Mold Product Info 1)Material: AS,ABS,PC,PS,PP,PVC,PBT,HDPE,PMMA etc. 2)Mould Cavity: Single or multi-cavities. 3)Mould material:Steel1045,P20,Cr12,DC53,H13 etc. 4)Surface Finish: chr

| Product Info | 1)Material: AS,ABS,PC,PS,PP,PVC,PBT,HDPE,PMMA etc. | ||||||||

| 2)Mould Cavity: Single or multi-cavities. | |||||||||

| 3)Mould material:Steel1045,P20,Cr12,DC53,H13 etc. | |||||||||

| 4)Surface Finish: chrome plating,silk-printing,texture,color painting etc. | |||||||||

| 5)Injection machine production ability:from 0.1g to 6000g | |||||||||

| 6)The product in the pictures are our customers'OEM products, it's only for reference. | |||||||||

| The Introduction of Mould | |

| Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mould type | Injection plastic mould |

| Product material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Mould base | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mould runner | Hot/Cold Runner |

| Mould tooling equipment | Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| De-mould Type | Automatic Ejector |

| Maximum mould size | 1500*1500 mm |

| Gate | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Cavity | Single or Multi cavities |

| Mould Life | 45#:300,000 to 500,000 shots |

| P20:600,000 shots | |

| 718: 800,000shots | |

| Lead time | About 3-4 weeks |

| Package |

Wooden packing box or as customer's requirements |