中文

ENGLISH

中文

ENGLISH

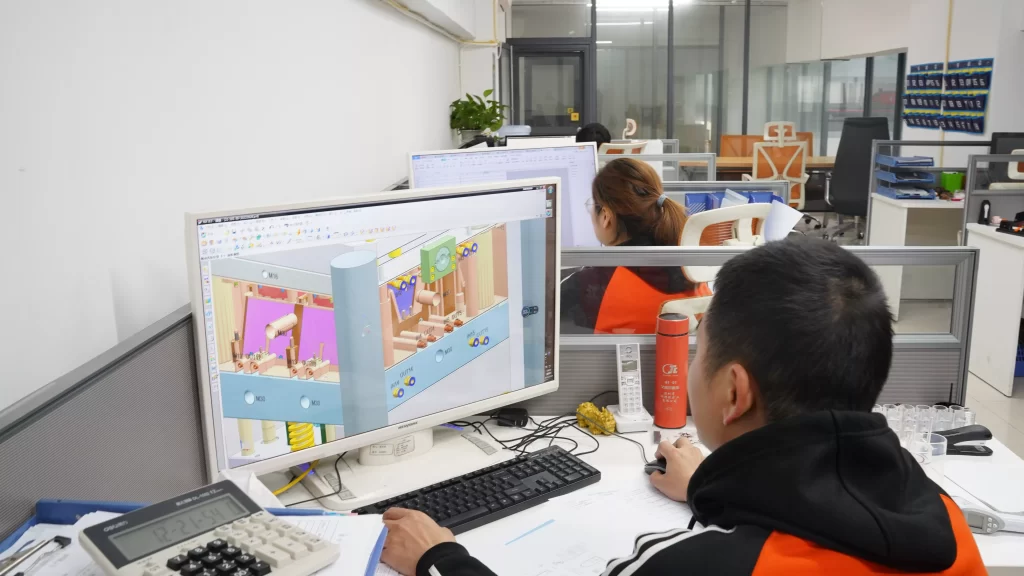

Precision mold making service

Precision mold making service -Rapid-MFG Need mold making supplies for mass-production parts? With our in-house mold making facilities and the resources of our partners, we can provide injection molds for hard plastics and rubber, metal injection mol

Need mold making supplies for mass-production parts? With our in-house mold making facilities and the resources of our partners, we can provide injection molds for hard plastics and rubber, metal injection molds for all types of precision stainless steel parts, and die-casting molds for aluminum, magnesium, and zinc. We offer cost effective, high quality molds to meet all your project needs. In addition, we provide long-term mold service maintenance and improvements for new product requirements. Using our CNC machinery, EDM technology, and the skills of our experienced mold makers to meet your mold build and specified surface finish requirements ultimately, such as Mold-Tech texturing or high polish SPI grade mold finishes. Vowin will provide the mold that meets your needs to assist in quality injection molded parts. Our in-house engineering department is available to assist with part design work.

Vowin can handle it without a hitch, whether you need a prototype mold for small production runs or a mass production mold for millions of runs.

Mold making is a complex process that requires a high level of skill and experience. Although each case is different, a typical order for a set of molds may go something like this:

As soon as the customer confirms the order of molds, we will start to do an initial analysis of the parts to get an idea of the part line, gate positions, etc.

The second step involves the use of predictive modeling software which allows us to see how the molten material will behave when it enters the mold, allowing for further improvements to the design.

We make the first molds using high-quality machining equipment, with the plastic, steel, aluminum, etc. chosen by the customer.

With the newly made molds, we make a T1 sample to have a clear vision of how the customer’s final molded parts will turn out.

Based on our analysis of the T1 sample, we review the mold design and make any adjustments needed.

We manufacture the molds in accordance with the final specifications before shipping them to the customer.

Competitive

One to One Service

Enginner Review

Quality

Fast Delivery

Request Quote Right Now