中文

ENGLISH

中文

ENGLISH

If you are planning to create a plastic product, you need to find the best injection moulding die manufacturer in town. However, before you go down that road, it is imperative to have knowledge about some basic concepts of plastic vowin.cn/en/News/news1251.html' target='_blank'>vowin.cn/' target='_blank'>molding.

Regardless of the product type that you are planning to purchase, may it be playground equipment or a plastic kayak, you are making an investment. You would narrow down your options while keeping the ROI factor in mind. Therefore, we highly recommend that you weigh the benefits of rotational molding as well as plastic injection molding before you finalize the manufacturing process.

Once, you understand the difference, you will be in a better state to make a knowledgeable decision. So, here we go!

Roto molding or more formally known as the rotational molding is a production technique that manufacturers use to create hollow parts of limitless sizes. The technique involves multiple layers, thus making it possible to manufacture large parts at affordable prices.

Using the rotational molding process for manufacturing poly-based products yield effective results. Manufacturer pours plastics or resins usually in the form of power into a hallow mold. After that the mold is bolted tightly to ensure that no product dispenses once, their rotation starts.

After securing the mold, place it into an oven. Then rotate the mold at an even speed. The rotations take place both in vertical as well as horizontal planes. The constant rotation along with the heat melts the resin and distributes if evenly inside the mold. This would ensure even distribution of the melted powder inside the mold.

The outcome of the process is a pre-designed part. The part would have a uniform wall thickness, thus ensuring its quality and robustness. Also, do bear in mind that the corners for the parts created using the rotational molding technique are denser.

The reason being, the material tends to accumulate at the edges and corners of the mold. In case, you want to avoid this, you would have to opt for another molding technique. We will talk about that also later in this article.

For now, let’s focus on the advantages the rotational molding technique has to offer.

Below are the top advantages of using roto-molding.

Rotational molding offers design flexibility. Thus, allowing the manufacturing of highly complex parts. So, if the part of the component is geometrically complex, use rotational molding for superior parts and better manufacturing quality.

The moulding procedure yields better results. It ensures even spread of the plastic power across the inner walls of the mold. Thus, resulting in a flexible, stronger, and robust end product. It is highly effective for products that will be exposed to a rugged environment.

These parts can stand high temperatures as well as the low ones without cracking or breaking. The reason being, the rotational moulding technique eliminates the stress points as it has more thickness at the edges and corners of the parts.

With rotational molding, it is possible to achieve consistent wall thickness. This further enhances the overall strength and robustness of the product.

Since the tooling required for the rotomolding is inexpensive, thus it is preferred by manufacturers around the globe. The inexpensive tool would lead to lower-priced components and parts. Thus, luring more and more consumers.

In addition to manufacturing high-quality products, the process also ensures limited production time. It means, it can do mass production in a limited time. Something, everyone wants. After all, there is a race out there and the one wins, take it all.

With rotomolding, it is possible to effortlessly remove the throughput. After all, the technique does decrease the labor hours in an effective manner.

Parts created using the rotational moulding lack the welding lines or the parting lines. Their surface is clear of all imperfection. In most cases, there is no need for additional work on the product, after it comes out of the mold.

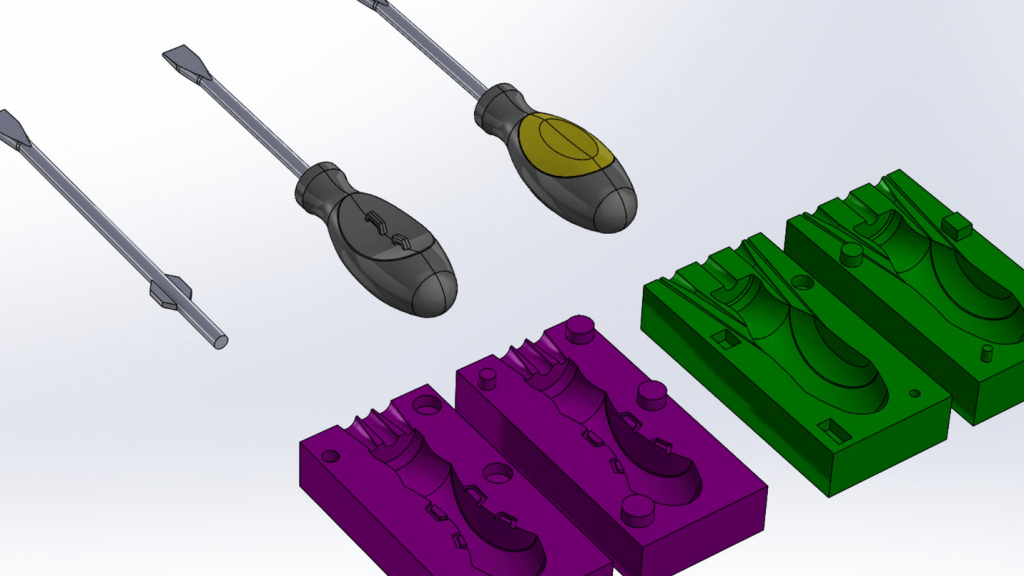

The injection moulding die manufacturer injects a melted plastic mixture using high pressure into a mold’s cavity. Before injection, the plastic is hot. It tends to cool down within the wall of the mould, thus taking up its shape.

It is possible to design the mould into any size or shape. In order words, you can design the mold according to the requirement of the end product.

NOTE: Designing a mold requires skills and expertise. Imperfection in the mold would result in errors in the final part or component.

Manufacturers use either steel or aluminum to create the mold. They use a mold to create identical copies of a single part. Thus, it is extremely useful in mass production. You can also use mould to create multiple parts that would come together to create something bigger and more complex.

An Injection moulding die manufacturer would recommend injection molding when you want to create multiple copies of the same component or the part. It is an effective plastic manufacturing process.

With injection molding, it is possible to create extremely complex designs. Creating molds is a challenging task. However, it offers the facility of creating your desired shape. It means the mold takes up any shape that you like.

Once the mold is ready, you are free to create as many parts and components as you like, regardless of their complexity level. The injection molding technique is popular for creating kitchen appliances, knobs, bottle caps among other things.

Unlike the rotational moulding technique, where manufacturers have access to a limited number of materials. Injection molding offers diversity in terms of material. You can use several materials to create parts and components.

Learn more about the Processing of Plastic Injection Molding Parts.

The injection moulding technique is more cost-efficient in comparison to the rotation moulding. It does not use the additives which increase the price of the rotation moulding. However, additives do offer some benefits.

So, to incorporate those benefits into injection molding, the injection moulding die manufacturer, uses additives for this type of molding as well. In addition, injection molding is extremely affordable, especially for bulk manufacturing.

It is preferred for mass volume as it can produce more items on the production line. Thus, decreasing the overall manufacturing time of the components and parts.

Both plastic and injection moulding technique has its own benefits and demerits. So, it greatly depends on your product requirement. If you are planning to produce a limited number of parts or components, you have the time and you do not want to compromise on quality, go with rotational molding.

On the other hand, if your objective is mass production. You want the parts to be ready in limited time and you need the overall cost to be low, injection moulding would do the trick. Although, bear in mind that with injection molding, the quality deteriorates.

Of course, you can boost quality by including additives. This would allow you to enhance the overall quality and finish of the products and parts.

Here are some additional Benefits of Injection Molding.

If you are still confused between the two moulding processes, you can reach out to one of our representatives. They would be able to answer all your quires regarding different moulding techniques.

In addition, our years of experience in designing and developing parts and components would help us guide you in the best possible way. We, Kaito Mould, are after all among the leading moulding manufacturers.

We create robust, high-quality and fine plastic components or parts that would meet all your requirements in an effective manner. Thus, ensuring quality while being affordable.