中文

ENGLISH

中文

ENGLISH

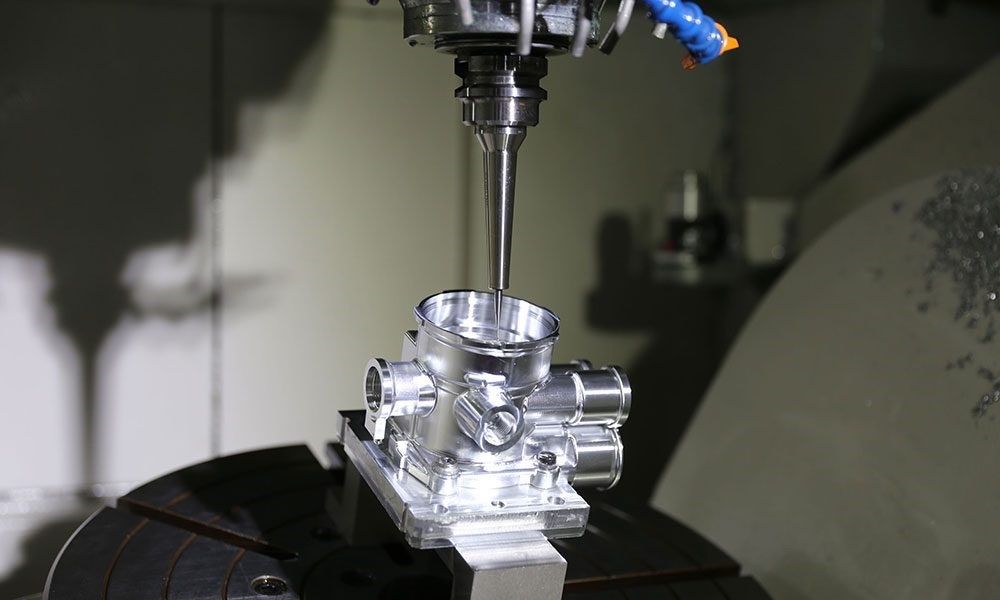

CNC vowin.cn/en/News/news1251.html' target='_blank'>machining service helps you to manufacture and create the different parts of the metals according to the requirement. This process is also helpful in the creation of the large variety of the tolerance of the materials and metal parts. This process is generally a subtractive method to produce the metal parts.

This article will help you understand the process of CNC machining services. It will also illustrate the working of the CNC milling and cutting machines in this process. It will also describe the steps and methodology in the process of creating the metal parts by CNC machining service.

CNC machining is a process that is helpful in the cutting of the different materials. The cutting of the materials helps in the creation of the different sized and shaped metal parts. Thus, this process is actually the removal of the materials from the surface of metals in order to modify it.

The cutting process of the CNC machining uses different types of the cutting tools. Different kinds and varieties of the cutting tools are available in the market. These help to cut and trim the metals for the creation of the different metal parts. All the process has control from a computer. That is why, it has name of computer numeric control machining.

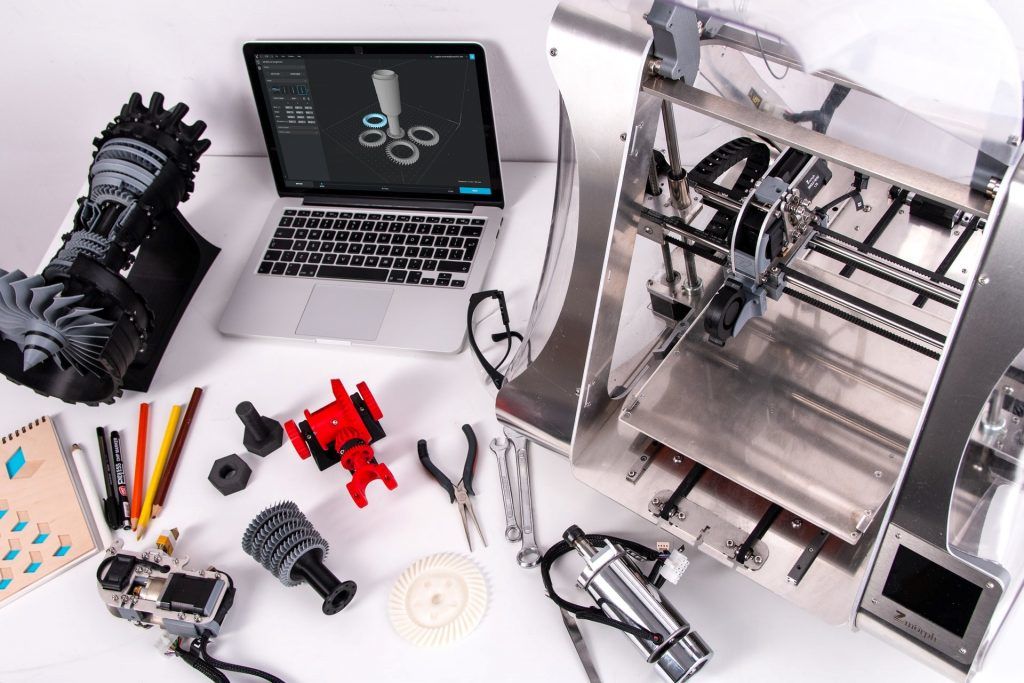

The process of CNC machining service includes certain steps in the way. The first step of the process is the formation of the design of the part which we have to create. The design formation of the part is the function of CAD (computer aided design) software. We can producer the design of our requirement on this software with the help of computer.

The next part of the process is the conversion of the design into the physical form. This step of the process is the function of CNC machine. The CNC machine recognizes the design of the part and converts it into the physical appearance. The machine works according to the instructions that we give it through software.

In the process of the creation of the metal part, there is a significant contribution of the worktable of the machine. The function of the worktable of the machine is to hold the material in the place. The piece of the material that the worktable holds in the place is work piece. In this way, worktable is important in the effective running of the machine.

The worktable of the CNC machine has the ability to move in the CNC machining service. However, this table may not move according to the design of machine and type of the process. Some machines have the moving worktable while others have stationary worktable according to the condition of the project.

When the machine starts the cutting process, the worktable helps to bring the cutting tool near the work piece. Thus, the cutting tool comes close to the workpiece and starts cutting it. Thus, the machine cuts the material in a way that it cuts out the layers of the material upon its surface. The cutting process goes exactly according to the instructions from the computer.

The worktable of the machine or the workpiece moves or rotates during the process. However, this rotation is according to the G-code instructions from the software having the design of the metal part. In this way, the cutting of the layers of the material proceeds according to the design requirements from the software. This process continues until we obtain the final part of the finishing product.

There are different types of the CNC machines used in the CNC machining service. The CNC machines include the CNC milling machines, CNC turning machines, CNC lathe machines, CNC routers and electrical discharge machining (EDM) machines. Let us have some description of these CNC machines.

CNC milling machines are the important type of the CNC machines. They have the specified cutting tools with them. These tools are important in the cutting process of the parts of the material. Moreover, these machines have the ability to rotate according to the design requirements of metal part. So, they can cut the material at the different angles and areas to make the perfect design.

The CNC lathe machines have the different type of working as compared to the CNC milling machine. These machines do not rotate themselves. But they rotate the workpiece in order to do the different types of the cutting actions. The cutting tools of these machines are stationary and do not move or rotate.

In this way, the workpiece rotates and moves according to the requirement and a fine piece of the product is available after the process. The CNC lathe machines are specifically important in the creation and fabrication of the cylindrical parts of the materials.

The CNC router machines have the similar working and functioning as the CNC milling machines. However, there is a difference between these two. The difference is that CNC routers are unable to cut the hardest metals easily. They are important in the cutting of the soft materials. However, these machines are faster than the CNC milling machines.

The electrical discharge machining (EDM) machines are the CNC machines that do not use the cutting tools in the cutting process. They use the electrical discharges or sparks in the process to cut the materials. However, there is no physical contact between the CNC machine and the material.

The specific feature of the CNC machines is the number of axis for the machines. The more the number of axis the machine is capable to move, the complex design it can generate. More number of axis help in the creation of the complex and complicated parts of the metal parts.

The CNC machining service is a helpful process in the creation of the different types of the metal parts with an ease. We can generate the plastic and metal parts in any volume or amount according to our requirements or needs. Thus, this process helps us in the creation of the best and efficient metal and plastic parts in the bulk amount.

This machining service helps us escape the high expenditures of the tooling and hardware uses. Moreover, we can also save our budgets from the use of the expensive set ups and tools. In addition, the machining process is equally helpful in the formation of the simple as well as the complex designs.

We can use a wide range of the materials in the CNC machining service. These materials include the plastics, aluminium, titanium, brass, steel, metal alloys and other important materials. The use of the type of material depends upon the nature of the metal part we have to fabricate.

Different project and customers need the different type of the parts made of different materials. In this way, the materials that we use in the machining process also vary according to the condition.