中文

ENGLISH

中文

ENGLISH

Are you in search of prototyping manufacturers to help actualize your ideas and help you with your product development? This article is for you. A good manufacturer offers high quality, fast turnaround, and cost-effective vowin.cn' target='_blank'>rapid prototyping services to customers all over the world. A reliable company is equipped with advanced manufacturing technology, has a team of expert engineers, and advanced industrial-grade equipment that will let you bring your idea from design to the market within a few days.

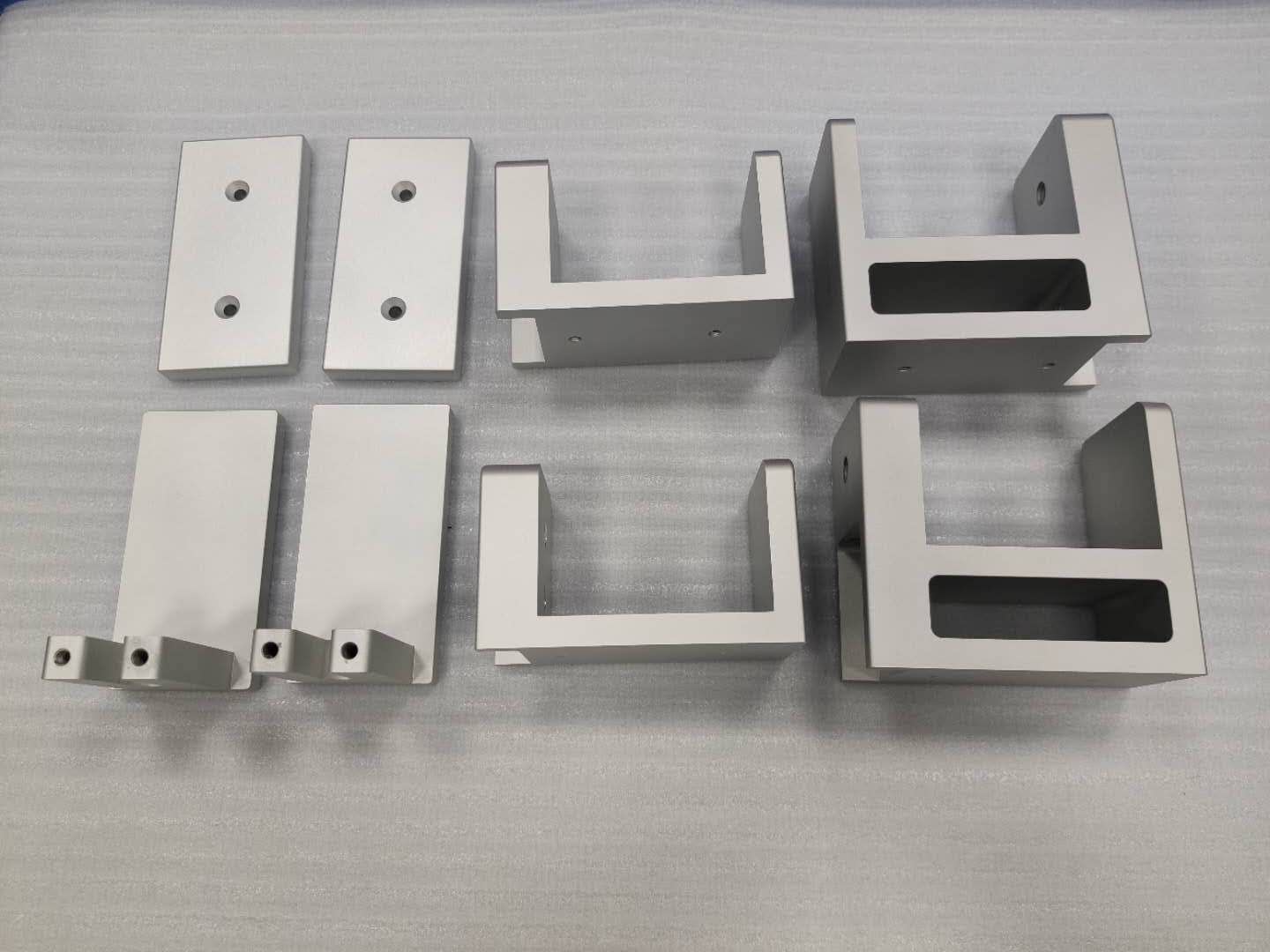

These prototyping manufacturers also provide on-demand manufacturing services using an advanced process like CNC machining, injection molding, 3D printing, vacuum casting, and much more. Whether you are an engineer, a startup technology company, or an industrial design agency, there is a company fit for your prototyping requirements.

Advantages of Rapid Prototyping

Some of you might be wondering why you need rapid prototyping. Your company can benefit a lot from this process, and some of the advantages of using it are as follows:

Through rapid prototyping, you will be able to explore and realize concepts in an easy, fast, and least expensive manner. The turnaround time is much faster, and it will not cost you that much. It enables your team to move beyond the visualization of an idea, which makes it simpler to understand the properties and design of a product in the actual world.

Repeat designs and integrate changes that enable for improved assessment and functional testing of the product. This process provides a plan for developing and improving the end product before bringing it to the market, which makes sure that the design is enhanced and foolproof.

You can physically present the concepts precisely and effectively. Rapid prototyping takes images, concepts, and ideas from one or two-dimensional visuals into actual products that colleagues, collaborators, and clients can take hold in their hands and see how it works.

The concept is tested and refined thoroughly. This minimizes design errors and flaws with a small quantity rapid prototype run. It reduces cost on expensive design flaws that could be seen on early assessment.

Saves time and money by getting rid of the setup and tooling process. Since the company can utilize the same machine to create different prototypes with various materials and properties, the total costs and turnaround time are at a minimum.

Pre-production and Manufacturing

Once you have the prototype, the design is economically and repeatedly manufactured to produce a successful end product. Design for Manufacturability keeps the functionality and aesthetics of the product in balance without affecting the requirements of the final product. The Design for Manufacturability hastens the manufacturing process to lower the manufacturing costs and keep it at the required level.

Rapid prototyping enables engineers to produce small-batch runs, sub-assemblies for engineering, one-off custom solutions, and design validation builds to test manufacturability.

With 3D printing, it is much easier to test tolerance with the manufacturing process in mind and to do comprehensive field testing and in-house before proceeding to mass production. 3D printed parts likewise support production, molds, fixtures, with prototyping tools, and others