we provide the Engineering Review for customer drawing, mechanical engineering review, electrical engineering review center, Production Engineering Review, Product Development, Sample test, jigs design, jigs make, Fixtures make, Fixtures d

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools.

Description[edit]

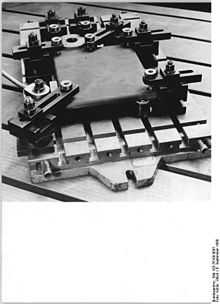

Device with grooves and chucks

A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.[1] A jig is often confused with a fixture; a fixture holds the work in a fixed location. A device that does both functions (holding the work and guiding a tool) is called a jig.[citation needed]

An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory. Jigs may be made for reforming plastics.

Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one is custom-tailored to do a specific job. Many jigs are created because there is a necessity to do so by the tradesmen. Some are made to increase productivity through consistency, to do repetitive activities or to do a job more precisely. Jigs may be well made for frequent use or may be improvised from scrap for a single project, depending on the task.

Some types of jigs are also called as a templates or guides. Jigs include vowin.cn/en/News/news1251.html' target='_blank'>machining jigs, woodworking jigs (e.g. tapering jig), welders' jigs, jewellers' jigs, and many others.

Drill jig[edit]

A drill jig is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole center. In metalworking practice, typically a hardened drill bushing lines each hole on the jig plate to keep the tool from damaging the jig.

Drill jigs started falling into disuse with the invention of the jig borer.

Since the widespread penetration of the manufacturing industry by CNC machine tools, in which servo controls are capable of moving the tool to the correct location automatically, the need for drill jigs (and for the jobs of the drill press operators who used them) is much less than it used to be.

PCB jig[edit]

Printed circuit board (PCB) jigs are used to test PCBs. They have a dump board inside the jig which can find faults in the PCBs.